- Home

- About us

- Products

- Bitumen Grades

- Specifications

- Bitumen 10/20 Specifications

- Bitumen 20/30 specifications

- Bitumen 30/40 specifications

- Bitumen 40/50 specifications

- Bitumen 50/70 specifications

- Bitumen 60/70 specifications

- Bitumen 60/90 specifications

- Bitumen 80/100 Specifications

- Bitumen 85/100 Specifications

- Bitumen 100/120 Specifications

- Bitumen 120/150 specifications

- Bitumen 150/200 Specifications

- Bitumen 200/300 Specifications

- Bitumen VG 10 specifications

- Bitumen VG 20 specifications

- Bitumen VG 30 specifications

- Bitumen VG 40 specifications

- Analysis Record of Vacuum Bottom Properties

- Oxidized Bitumen

- Cutback Bitumen

- Bitumen Emulsion

- Polymer Modified Bitumen (PMB)

- Penetration Value of Bitumen

- Bitumen Viscosity Grade (VG)

- Application of Performance Grade (PG) Bitumen

- Services

- Why choose us?

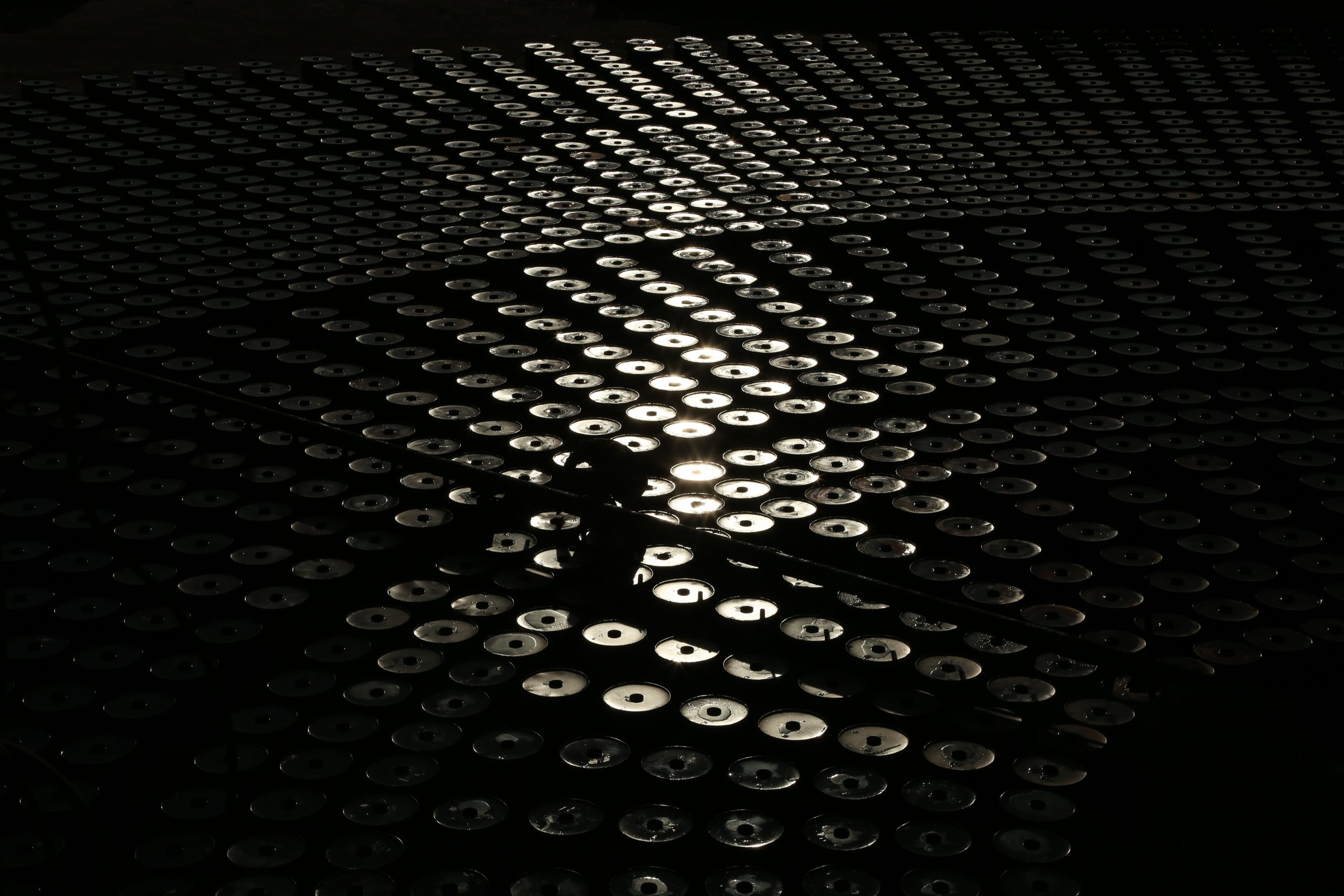

- Gallery

- News

- Certificate

- Contact Us

- catalogue

Bitumen is produced by the distillation of crude oil, or simply found in nature. Bitumen is a petroleum-based material, used for binding stones and sands and producing asphalt for road construction. In the normal process of an oil refinery, crude oil is heated in an atmospheric distillation column. This will lead to the separation of various parts of crude oil according to their molecular weight. The heaviest part of the oil that remains at the bottom of the distillation column, is called Vacuum Bottom and forms the raw material for producing refined bitumen.

Based on the source, bitumen’s physical properties such as consistency, stiffness, viscosity, adhesion, and durability may differ. Therefore, it is crucial to becoming more familiar with bitumen’s occurrence in nature and bitumen as a byproduct of crude oil.

Bitumen is an adhesive material composed of complex hydrocarbons. This high viscose material contains elements such as calcium, iron, sulfur, and oxygen. Bitumen has a remarkable ability to change with temperature variations. At lower temperatures, this material is rigid and brittle, at room temperature, it is flexible, at higher temperatures bitumen flows.

Bitumen was first used for adhering woods to stone tools some 40,000 years ago (by Middle Paleolithic Neanderthals). Afterward, bitumen was used as an adhesive material in a wide variety of applications.

Bitumen has also a unique density and viscosity in comparison to other byproducts of crude oil. Due to the presence of large hydrocarbon molecules known as asphaltenes and resins, which are present in lighter oils but are highly concentrated in bitumen, bitumen has become useful material in binding stones and sands for road construction.

Although large natural reservoirs of bitumen exist in many parts of the world, most of the bitumen produced in the world is derived from crude oil. Natural bitumen extraction is more complicated than refining bitumen, therefore it will cost the producers more. It is also interesting to know that natural bitumen contains up to 5% sulfur, heavy metals, and other impurities that must be refined.

For processing vacuum bottom and producing bitumen, we transfer it to another refinery. There, we use various methods of processing VB, including blowing, blending, mixing vacuum bottom with water or solvents, and modifying it with polymers, so that we can provide the bitumen market with various types and grades of bitumen.

The process of separating bitumen from crude oil begins in the atmospheric distillation column, followed by a heating process in which the crude oil evaporates. The vapor flies cools and becomes liquid again. Distillation trays in the column will enhance the process of liquid separation according to the molecular weight. The heaviest part of the oil that remains at the bottom of the distillation column, is called Vacuum Bottom, and form the raw material for producing refined bitumen. Properties and quality of bitumen depend mainly on the crude oil used in its manufacturing process.

Bitumen can be further processed by blowing air through it at elevated temperatures. For this the Vacuum Bottom is transferred to the vacuum distillation column, to go through a blowing process. A mild degree of air-blowing is commonly used to make a minor adjustments to the physical properties of the vacuum bottom, such as decreasing the penetration of the bitumen. In this stage, various types of bitumen which have more asphaltene and molecular weight, with higher penetration value are produced.

Production of Bitumen by refining crude oil is highly economical. In the distillation process of crude oil, which is essential for producing petrol, diesel, high octane fuels, and gasoline, bitumen is left behind and can be used easily after processing.

The bitumen can be classified into the following grade types:

- Bitumen Penetration Grade

- Oxidized Bitumen Grades

- Cut Back Bitumen

- Bitumen Emulsion

- Polymer Modified Bitumen