- Home

- About us

- Products

- Bitumen Grades

- Specifications

- Bitumen 10/20 Specifications

- Bitumen 20/30 specifications

- Bitumen 30/40 specifications

- Bitumen 40/50 specifications

- Bitumen 50/70 specifications

- Bitumen 60/70 specifications

- Bitumen 60/90 specifications

- Bitumen 80/100 Specifications

- Bitumen 85/100 Specifications

- Bitumen 100/120 Specifications

- Bitumen 120/150 specifications

- Bitumen 150/200 Specifications

- Bitumen 200/300 Specifications

- Bitumen VG 10 specifications

- Bitumen VG 20 specifications

- Bitumen VG 30 specifications

- Bitumen VG 40 specifications

- Analysis Record of Vacuum Bottom Properties

- Oxidized Bitumen

- Cutback Bitumen

- Bitumen Emulsion

- Polymer Modified Bitumen (PMB)

- Penetration Value of Bitumen

- Bitumen Viscosity Grade (VG)

- Application of Performance Grade (PG) Bitumen

- Services

- Why choose us?

- Gallery

- News

- Certificate

- Contact Us

- catalogue

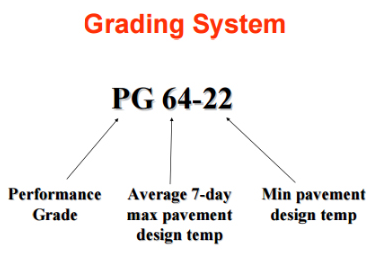

Performance Grade (PG) Bitumen is bitumen which is graded based on its performance at different temperatures. In Super pave grading system, binders are classified according to their performance in extreme hot and cold temperatures and called as performance grade (PG) bitumen. The main purpose of grading and selecting asphalt binder using the PG system is to make certain that the binder has the appropriate properties for environmental conditions in the field. PG asphalt binders are selected to suit the expected climatic conditions as well as volume adjustments and traffic speed. Therefore, the PG system uses a set of tests to measure physical properties of the binder which can be directly related to field performance in the paving situation.

Performance Grade (PG) bitumen is categorized based on traffic and pavement temperature. Modification and monitoring done here, are meant to simulate conditions and traffic volumes to enable us to longer the life span of the pavement and enhance the quality. The PG grading system is defined by two numbers, representing the pavement temperatures. The first number e.g.: PG 64-XX represents the highest pavement temperature in Celsius, while the second number e.g.: PG XX-22 represents the lowest. Note that these numbers are pavement temperatures, not the air temperatures (these pavement temperatures are derived from air temperatures). The high temperature is related to the effects of rutting and the low temperature relates to cold results such as fatigue cracking.

Performance Grading Should consider the actual conditions of different paving projects, since it’s dominantly used for paving, such as strain relationship under the field load, traffic speed and volume and the pavement structure.

Performance Grading Should:

- Include measures describing stress:

strain Relationships under field loading.

- Consider the pavement conditions:

Temperature, traffic speed, traffic volume, and pavement structure.

- Include acceptance limits derived from experience and actual field performance:

Variables that affect Binder Selection

- Geographic Area:

Air Temperature, solar radiation

Pavement Temperature: Max & Min

- Traffic volume: High, Medium, Low

- Traffic speed: Fast, Slow

- Pavement Structure: Strong, Weak

Stress and strain

Methods of Selection

- Select base grade based upon:

Geographic Area

Air Temperature

Pavement Temperature

- Adjust base grade based upon:

Traffic Speed

Traffic Volume

PG52-28 is dominantly used in paving for both new construction and road care and also in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing cracks in paving and also the edges. Other applications include spraying in places like bridge deck and pavement protective membrane with fabrics.

PG58-22 is initially used in paving for both dense-graded and open graded Hot Mix Asphalt (HMA) and also in road construction usages as well as spraying and crack sealing applications.

This grade is widely used in very cold areas.

PG58-34 is generally used in the higher elevation roadways. This grade is a paving asphalt cement dominantly used for the production of Hot Mix Asphalt (HMA). It could also be used for sealing the edges of new to old paving and cracks sealing.

PG58-40 is primarily used on the high elevation locations. This grade is paving asphalt for the production of Hot Mix Asphalt (HMA). It can be easily used for sealing purposes and crack treating as well.

PG64-22 is mostly used in paving for both new construction and pavement treatment projects and in both dense-graded and open graded Hot Mix Asphalt (HMA) as well as others. It can be easily used for sealing purposes and crack treating too. Other uses include spray applications for bridge decks and pavement protective layer with fabrics and some modifications. It has been reported that with proper aggregate selections and asphalt content, HMA with PG64-22 as the binder may show less tenderness compared to a similar mixture with a lower viscosity/softer asphalt. This will lead to a significant reduction of typical tenderness problems of mixture shoving and checking during pavement surface scuffing and rolling and markings caused by traffic immediately after paving.

PG64-28 is primarily used in road construction and paving for new and pave care projects and in both dense-graded and open-graded HMA. Other uses include spray applications for bridge deck and pavement protective layer with fabrics. PG64-28 is generally used for the locations with low elevation.

PG70-22 is primarily used in areas with high traffic volume and is also the paving asphalt cement used for the production of Hot Mix Asphalt (HMA). This grade is also a good choice for sealing the edges of pavement and for crack sealing.

PG Grades with the best resistance in thermal cracking

- PG 64 -22

- PG 76 -22

- PG 64 -28

- PG 58 -34

PG Grades with the best resistance against rutting

- PG 82 -22

- PG 76 -28

- PG 70 -28

- PG 76 -22

Common in toll roads (high Volume)

PG 64-22

Common in toll booth (high volume and slow traffic)

PG 70-22

Common in rest area (high volume and standing traffic)

PG 76-22